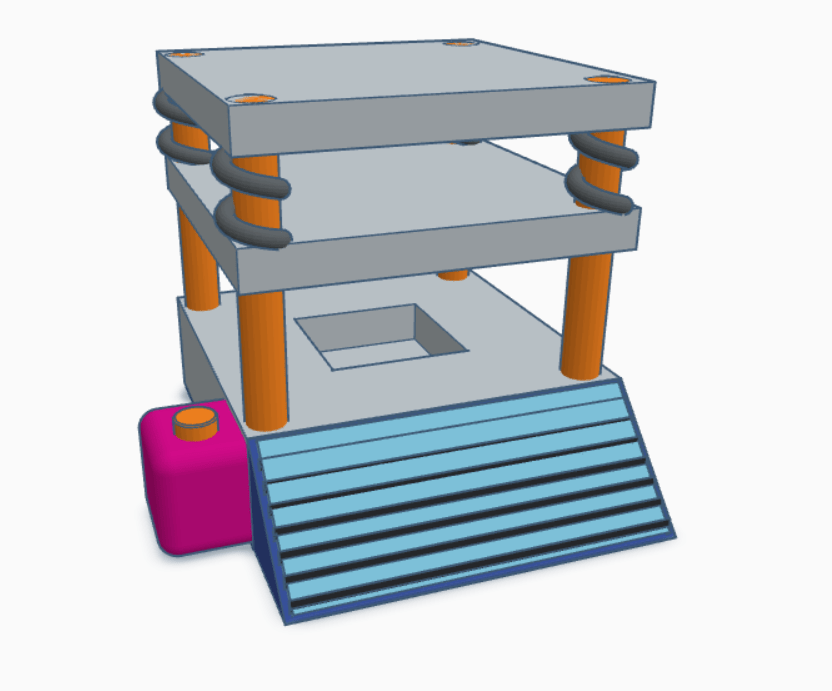

This post is more of a development blog tracking an idea I have to create a small scale plastic recycling device.

Plastic recycling is a difficult and expensive process and it really doesn’t happen on a large scale like we need it to be. One of the biggest inspirations for my idea is the incredible Precious Plastics project: https://preciousplastic.com/

I have been introducing their work and doing some small scale techniques in my classroom for 3 or 4 years now. Teaching pupils about materials sciences, the history of plastic and what can realisticly be done.

One issue with recycling plastic, is that it takes a lot of energy to do it. So much so that Lego themselves recently announced they weren’t going to continue on their project to use recycled plastic to make bricks as it actually would end up with a higher carbon footprint.

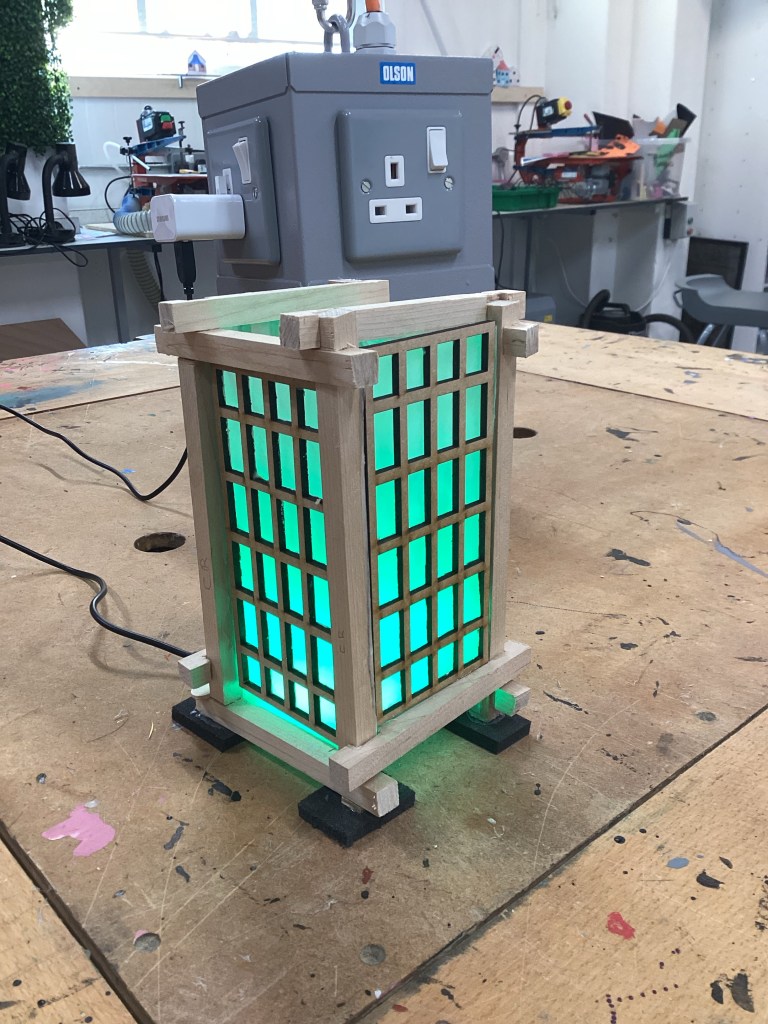

So, my plan is, super small scale plastic recycling using renewable energy. Open source the blueprints and files needed for other people to make their own.

- TO WORK OUT:

- how much plastic is in a bottle cap and how much energy would be needed to melt it.

- Can we use capacitors to store enough energy to heat the plate enough

- Would it be worth having just one metal mould or have it modular so different things can be made

- Circuitry for safe energy regulation

- WOuld it be worth adding something like a dynamo so people can speed up the process by hand?

- Temperature regulation so that it doesn’t over-heat and burn the plastic. – 3D printers are a good place to look at for this. Probably achievable on a raspberry pi pico.

I will update this post whenever I make any progress. If you’re interested in getting involved, do get in contact!

update 1 – some simple calculations:

there is 2.2g of plastic per lid

a 4×4 stud lego plate is 2.2g

the plate is 32 mm wide

So a metal mould should be 40x40x10 wide

An aluminium box of 40x40x10 = 40g

A plastic lid is made of hdpe with a melting point of 135C

To heat 0.04kg of aluminium to 135 degrees you need 4,843 joules of energy

Over 2 hours, that is equal to 0.67W of electricity

with 0.16 amps, it will need 4.18 volts.